| SIPING ONLY: Siping is a technique first patented in the 1920's by a man named John Sipe who came up with the idea of putting razor cuts in his shoes to give him better traction. When applying this technique to a dirt sprint tire, siping will do many things. First, this will help the tire build heat quicker which will help the tire "fire" better. Siping will also dissipate heat when the tire gets to operating temperature and the sipes open up. If you are using a fairly hard tire, siping will help create a "graining" effect which will help keep the tire from "sealing" over. The only sprint compound we do not normally recommend siping is a D10 tire because it is already very soft and may result in "tearing" of the tread blocks and will result in loss of traction. As such, you rarely see Hoosier sprint tires siped for qualifying since the D10 compound is normally the qualifying compound. Also, never sipe a tire more than half the depth of the tread block. Any deeper than half the depth of the tread block may cause the sipes to rip or chunk out. How much you sipe a tire will come from your own experience through trial and error. Also, like all good racers, pay attention to what techniques your competitors are using. They may have learned something you have yet to experience.

GROOVING ONLY: We recommend grooving a tire if the track is very wet and heavy or if the track is a hard surface with a lot of loose dirt blowing across the surface. Grooving will help channel the dirt out the tire to help maintain a good contact patch between the tire and track surface--just like the grooves in your street tire which help keep your car from hydroplaning. Grooving will also create more edges for better traction or grip. Just as with siping, how much you elect to groove your tires depends on what you have experienced in the past along with watching what the top finishing drivers are doing as well.

SIPING AND GROOVING: Combining both siping and grooving is normally done in both heat and feature races. You may need the grooves for cleaning but yet you also need to do some siping to help the tire "fire" and to allow the tread surface to properly "grain".

SIPING

|

|

Generally, the grooving blade is reversed to result in two independent cutting blades. The depth should be set no deeper than 1/2 the depth of the tread blocks. Deeper than 1/2 the depth may cause individual tread blocks to rip or chunk out. When setting the depth of the blades for siping, place the siping head on the tread block and visually adjust the depth to 1/2 the thickness of the block.

|

|

|

|

|

Proper siping of this tire has resulted in a very nice texture or grain to the tread surface. The siping allowed the tire to "fire" quickly on starts or re-starts and as the race went on, the sipes allowed heat to be expelled which resulted in less chance of blistering.

|

.jpg) |

|

|

|

A sipe is simply a razor thin cut or slit in the rubber tread block.

|

|

|

|

|

GROOVING

|

|

Straight grooves work best for forward bite. We recommend no wider than 3/16" wide of grooves. Wider than this may tend to cause the tread block to rip or peel back.

|

|

|

|

|

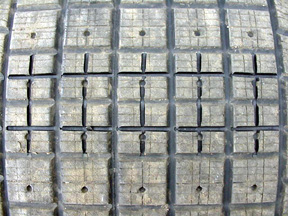

When using a very hard compound, you may want to 1/4 groove the tread blocks allowing for a greater degree of "cleaning" grooves and more edges for increased traction. Usually the tire is cut vertically and then horizontally or vice versa.

|

|

|

|

|

Grooves can also be cut at angles. Angled grooves will result in a combination of increased side bite as well as increased forward bite.

|

|

|

|

|

Unlike siping in which you should go no deeper than 1/2 the depth of the tread block, grooving can and generally is the full depth of the tread block. Also, the "hole" in the tread block(s) is called a "heat dispersion vent" which serves to reduce the chances of blistering.

|

|

|

|

|

Proper grooving and siping techniques will ultimately result in a better performing sprint tire which will in turn result in higher finishes.

|